PREtec

PREtec (Plant Response Elicitor technology) is our core new technology, inspired by harpin proteins found in nature.

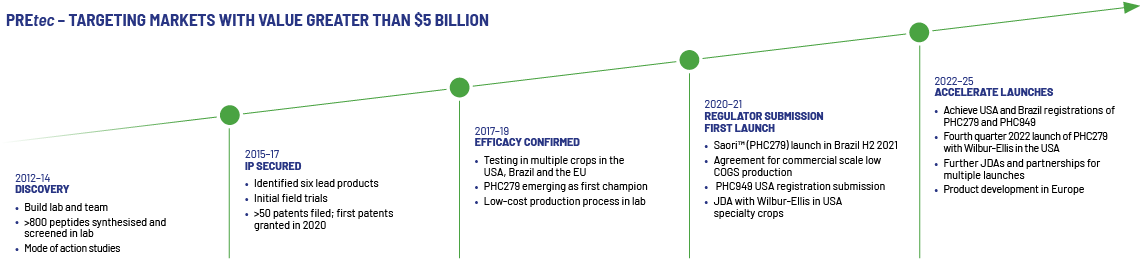

The PREtec technology platform is proving to be a reliable source for new products. After the launch of Saori® in Brazil in 2021 and Obrona® in the US in 2023, the pipeline is poised to launch one new PREtec product each year going forward. The bionematicide peptide, PHC949, is scheduled for commercial launch in Brazil in time for the 2024 soybean growing season. All PREtec peptides are variants of naturally occurring proteins and break down rapidly in the environment, leaving no harmful residues on the crop or in the environment. The Group has a long history of offering products that support agricultural and environmental sustainability. The new products described below continue to meet the highest standards of sustainability.

Read more on our Science in the Company's 2021 Annual Report.

PILOT SCALE MANUFACTURING OF PREtec PRODUCTS

Successful commercialisation of peptides is critically dependent on the development of low-cost manufacturing. The Group is committed to building on our existing lead in this regard, to ensure that we can offer the benefits of PREtec peptides to growers at prices which offer them substantial returns on their investment, while ensuring strong profitability for both Plant Health Care and our distribution partners. In 2021, the Group made a significant capital investment in production and scale-up capability, to support accelerated development of low-cost manufacturing processes for our current and future peptide pipeline. Large scale manufacture will always be outsourced, but the ability to develop detailed production processes for third party manufacturers is critical. Manufacturing at pilot scale also gives us flexibility, especially for launches and large-scale market development trials of new products and formulations. We are unaware of any company which can match PHC’s ability to develop high yield production methods for peptides. This is a key capability for the Group to retain in house, as we develop and optimise manufacturing methods for further leading peptides. Manufacturing technology can be transferred in a controlled manner to large-scale third-party production without losing the proprietary knowhow.

Capital was invested in the purchase of two 10-litre fermentation tanks and a granular dry formulation dryer, and the construction of a downstream processing line, which raised the processing volume from 5 to 50 litres. By the end of 2021, the pilot production facility was completed. These facilities will significantly accelerate the development of production process methodology for new peptides from the PREtec platform. The facility also enables us to produce 100 kg of peptide products per month, which will allow us to produce for small scale product launches.

Read more on our commercial scale production in the Company's 2021 Annual Report.